Thermometer manufactory

Precision thermometers manufactured by hand

Our eXacal precision thermometers are handmade in our factory in Fulda, Germany—and can even be customized to your requirements on request. We can implement individual changes to the handle, connector, or even the length of the sensor and connection cable.

The thermometers have been optimized for accurate temperature measurement. Depending on the model, they can be used in a temperature range from -200°C to 1200°C.

In addition to the design of the thermometers, another focus is on the development of our own tools and production processes. No external suppliers are required for the design, production, and final accredited calibration according to DIN EN ISO/IEC 17025 (DAkkS), apart from the raw materials. This independence ensures the high quality of the thermometers.

In the video you can see a tour of the thermometer factory:

An overview of the manufacturing process

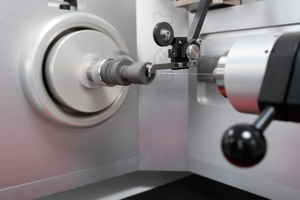

Mechanical manufacturing

Required components, such as handles or prototypes for further development, are produced by machining.

Noble metal welding process

Thermocouple wires and connecting cables are welded by hand with high precision. The gases needed for burning, hydrogen and oxygen, are not stored in bottles, but are produced from water in a 2:1 mixing ratio by electrolysis. This guarantees the purity of the fuel gas.

Laser welding

Extremely delicate connections, such as the connecting wires of the temperature sensors, are welded under the microscope with precision lasers.

Thermal processing of thermo material

One area of expertise is the specific thermal processing of thermocouple wires. Our annealing processes ensure a stable metallurgical and thermoelectrically homogeneous condition of the eXacal thermocouples. Thermal processing of thermo material

Annealing of resistance thermometers

Resistance thermometers are completely annealed according to our customised annealing cycles in a specially designed annealing furnace with oxygen circulation.

Winding wire coils

For our SPRT measuring resistors, high-purity, ultra-thin platinum wire is wound into a fine wire coil using a specially designed winding machine.

Cleaning ceramic components in a tube furnace

All ceramic components used in our precision thermometers are cleaned at high temperatures in a tube furnace before use.

3D printing process

Insulation components and complex plastic parts inside the handles, such as strain reliefs, are produced using a modern 3D printing process. This offers us many advantages. Complex designs are produced without manual workarounds and without expensive tools. This saves a lot of time and money. Using 3D printing, eXacal thermometers can be customised as a modular system.

Inhomogeneity scanner

Possible inhomogeneities of the eXacal thermocouples are analysed with the use of an inhomogeneity scanner. A moving heat source tests the entire thermal material of the thermoclouple for local inhomogeneities.

The inhomogeneity scanner is an own development of Klasmeier. With this, the thermocouples of eXacal Manufaktur can be significantly improved:

More realistic analysis of the measurement uncertainties

Verification of the thermal treatment

Improving quality and manufacturing processes

Questions about the eXacal manufactory?

Speak directly to our expert

Your contact person for the eXacal Manufactory:

Elke Seewald

Head of eXacal Manufacture